Custom packaging bags: Do you know all the essential knowledge about packaging?

Good packaging can ignite the entire marketing field, transforming an unknown small brand into a household name and capturing the hearts of consumers. You might think packaging is the most common and ordinary item in life, but it's undeniable that almost everything relies on it!

Packaging materials determine the function of the packaging. From traditional materials to today's new materials, the goal is to better serve the packaging's function. Today, composite packaging bags are irreplaceable in the packaging field. This packaging, made by laminating various plastic films, aluminum foil, paper, and other base materials with different properties, quickly replaced traditional packaging upon its introduction and is now increasingly widely used.

What are the characteristics of the packaging bags you use every day? Are they safe? What kind of packaging should you choose for your products? Today, Shunxingyuan Packaging, a professional flexible packaging manufacturer, will explain the characteristics, base materials, and applications of common composite packaging bags.

1. Characteristics of Composite Packaging Bags

So-called composite packaging bags are flexible packaging materials formed by combining two or more materials with different properties, creating a new high-performance packaging that fully utilizes the advantages of each component material. It combines the advantages of each layer of film while overcoming their disadvantages, resulting in an ideal packaging material that meets the requirements of various products.

With the advancement of material processing technology, today's composite packaging bags come in a wide variety of types and properties. Compared to other packaging materials, their main characteristics are as follows:

1. Lightweight, transparent, and soft;

2. Excellent airtightness and heat sealability;

3. Moisture-proof, air-proof, UV-resistant, heat-resistant, and cold-resistant;

4. Good dimensional stability, chemical stability, excellent chemical resistance, and oil resistance;

5. Tear-resistant, puncture-resistant, fatigue-resistant, impact-resistant, friction-resistant, and anti-aging;

6. Excellent machinability;

7. Exquisite printing and good visual appeal.

Composite packaging bags are lightweight, soft, produce little waste, are easy to process and shape, occupy little space, are low-cost, and have high cost-effectiveness (volume and weight per unit weight of packaging). They meet the needs of most goods, especially clothing, hardware, and food packaging.

2. Selection of Base Materials for Composite Packaging Bags

The base materials used in lamination are the main factors determining the properties of the composite film. The selection of base materials depends on the requirements of the packaged goods, the use of the composite material, and the properties of the single-layer film. In addition, the cost of the material must also be considered. A scientific, accurate, and reasonable selection must be made to meet the needs of different packaged contents. The properties of the plastics used in lamination are the main factors determining the properties of the composite film. The selection of base materials for composite films mainly depends on the following factors:

1. Properties of the composite film;

2. Properties of the contents;

3. Properties of the single-layer film;

4. Appropriate price of product packaging, etc.

Based on these factors, the appropriate lamination method and number of adhesive layers for the composite packaging material are selected.

3. Applications of Composite Packaging Bags

Composite packaging bags are mainly used for packaging clothing, apparel, hardware, food, pharmaceuticals, cosmetics, beverages, and other products. In recent years, global demand for composite packaging bags has continued to grow rapidly. A wide variety of base materials can be used for composite packaging bags. Commonly used base materials include: high-density, medium-density, and low-density polyethylene films (HDPE, MDPE, LDPE), oriented and unoriented polypropylene films (BOPP, CPP), polyester films (PET), polyvinyl chloride films (PVC), polyvinylidene chloride films (PVDC), nylon films (NY), etc.

Common types of composite packaging bags include: paper/plastic composite, plastic/plastic composite, and aluminum/plastic composite. The number of laminated base material layers can be two, three, four, five, or even more. Based on the type and thickness of the composite plastic film base material, the number and order of layers, and the lamination method, many types of composite packaging bags can be created.

Today, personalized packaging is a direction that many industries urgently need to change, helping companies understand the experiential consumption needs of target consumers in the broader environment, find the scenes they want to see, and combine their brand's tonality to create creative packaging. The various characteristics of composite packaging bags can deeply meet the needs of enterprises.

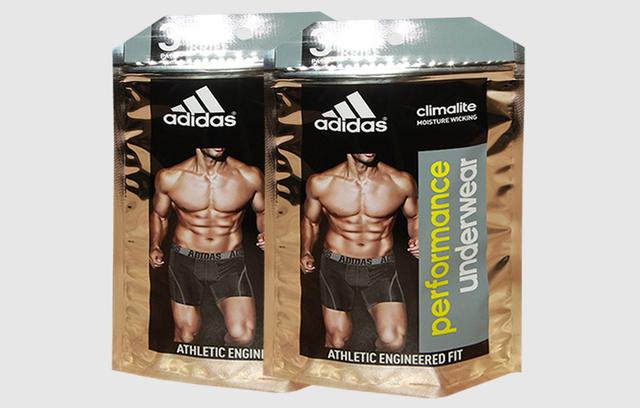

Major clothing brands such as Calvin Klein, G-Star RAW, and I.T have been constantly trying new packaging bags to make their brands more appealing. Packaging serves as a silent spokesperson, allowing Calvin Klein, G-Star RAW, I.T, and other well-known brands to shine on the stage with their unique brilliance.

Shunxingyuan Packaging provides strong support behind these exquisite packages. Shunxingyuan Packaging products feature exquisite printing and good texture, and can be customized according to customer needs. Clothing brands such as Calvin Klein, G-Star RAW, and I.T value these qualities and have established ongoing partnerships with Shunxingyuan Packaging. Shunxingyuan Packaging lives up to expectations, achieving a 100% on-time delivery rate and a 100% quality acceptance rate, and perfectly presenting the design styles of these major brands, making their products more competitive.

Good packaging not only protects the product but also greatly assists in aspects such as volume, shape, visual composition, instructions, and usage, thereby increasing the value of the product and establishing brand authority. Undoubtedly, to create good product packaging, choosing composite packaging bags with significant characteristics is equivalent to having a set of excellent marketing tools.

Scan the QR code to follow, Customize your exclusive packaging

www.dgsunpak.cn Shunxingyuan Packaging

Related Information

Proper use of food packaging bags

What types of clothing packaging bags are there? What is their scope of application?

What is a gusseted bag? What are the benefits of using gusseted bags?